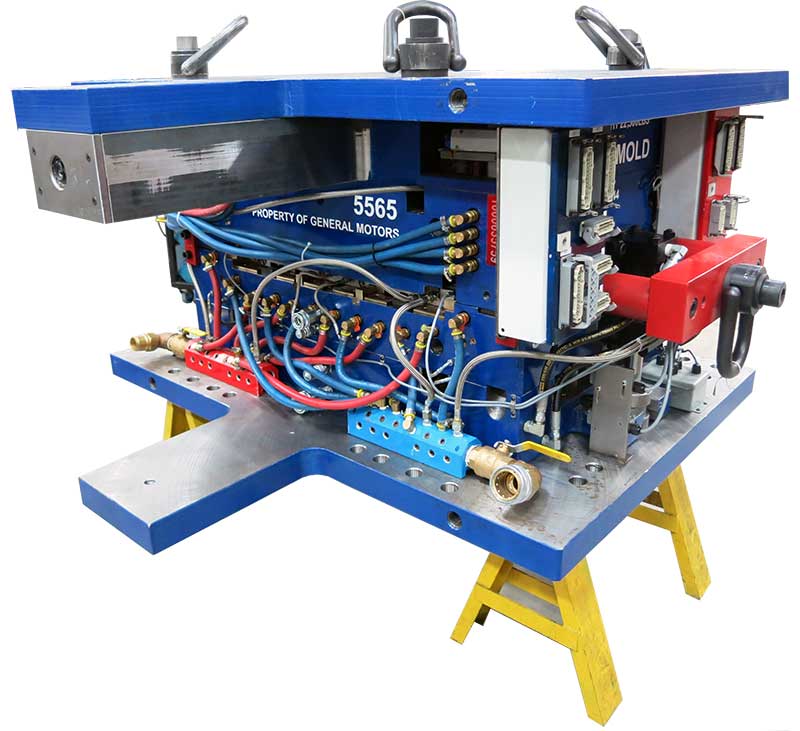

Full Service Mold

Manufacturing

Delivering Quality Molds at Competitive Prices

Why Superior is Different

Mold Types

Over 30 Years of Manufacturing Experience

Superior Tool and Mold has been designing, engineering, and manufacturing plastic injection molds since 1993. We provide solutions that cut lead times in all phases of manufacturing including automation. The company’s full-service tooling department specializes in the design and build of any type of injection mold in-house.

Manufacturing Equipment

CNC Department

Our continual investment in high end, high speed, 3,4 and 5 Axis CNC equipment gives Superior Tool the ability to handle large volumes of work with impressive results. Each machine has been equipped with the advanced FCS clamping system which has significantly reduced set up times.

We spare no expense when it comes to tooling and software to run our machines.

- Promac Zephyr High Speed 5-Axis

Travels: X=98″ x Y=70″ x Z=39″

Max. Table Load: 10,000 lbs

40 hp – 20,000 rpm

Spindle Taper – HSK 63 - Promac Zephyr High Speed 5-Axis

Travels: X=98″ x Y=70″ x Z=39″

Max. Table Load: 10,000 lbs

40 hp – 20,000 rpm

Spindle Taper – HSK 63 - Deckel Maho DMC 125U High Speed 5-Axis

Travels: X=49″ x Y=49″ x Z=39″

Max. Table Load: 4,500 lbs

70 hp – 12,000 rpm

Equipped With Pallet Change Tables

Spindle Taper – HSK 100 - Deckel Maho DMC 125U High Speed 5-Axis

Travels: X=49″ x Y=49″ x Z=39″

Max. Table Load: 4,500 lbs

70 hp – 12,000 rpm

Equipped With Pallet Change Tables

Spindle Taper – HSK 100 - Hi-Net DMC 1600H High Speed CNC

Travels: X=63″ x Y=51″ x Z=32″

Max. Table Load: 14,000 lbs

33 ½ hp – 15,000 rpm

Spindle Taper – HSK 100 - Starvision LG-3223

Travels: X=126″ x Y=90″ x Z=39″

Max. Table Load: 28,600 lbs

35 hp – 6,500 rpm

Spindle Taper – BT50 - Dynamic Speed DS SX7050 High speed CNC

Travels: X=28″ x Y=19″ x Z=15″

Max. Table Load: 1,000 lbs

32 hp – 36,000 rpm

Spindle Taper – HSK E50

CMM Department

- Faro CMM Arm

Working volume 9′ - Faro Edge Scan Arm ES

Working volume 9′

Boring Mill and Gundrill Department

- Doosan 4-Axis CNC Boring Mill

Travels: X=98″ x Y=78″ x Z=59″

Max. Table Load: 24,000 lbs

35 hp 4,000 rpm

Spindle Taper CAT 50 - IMSA 7-Axis Gundrill

Travels: X=80″ x Y=39″

Max. Table Load: 28,000 lbs

12 hp –

47″ drill depth

EDM Department

With the recent installation of two new large EDNC20 Sinker EDM’s and an Erowa Robot which sits between them, machining time has been reduced and is now three times faster.

Also just installed are an EDNC6 Sinker EDM and a 2nd Erowa Robot. This entire cell of EDM machines and an electrode cutting machine is managed and organized using JMS Pro Management Software.

Along with faster burn times, we have also seen a significant increase in surface finish quality and overall accuracy.

- Makino F3 High speed CNC – For Electrode Cutting

Travels: X=35″ x Y=19″ x Z=17″

Max. Table Load: 1,400 lbs

25 hp – 30,000 rpm

Spindle Taper – HSK F63 - Makino EDNC20 H.E.A.T. sinker EDM

Travels: X=86” x Y=40” x Z=32”

Tank Size: 118” x 62” x 41”

Max. Table Load: 22,000 lbs - Makino EDNC20 H.E.A.T. sinker EDM

Travels: X=86” x Y=40” x Z=32”

Tank Size: 118” x 62” x 41”

Max. Table Load: 22,000 lbs - Makino EDNC6 H.E.A.T. sinker EDM

Travels: X=26” x Y=18” x Z=14”

Tank Size: 43” x 29” x 17”

Max. Table Load: 3,300 lbs - Erowa Robot Compact 80 (x2)

- JMS Pro Management Software

Manages the entire EDM Department

Spotting Presses

- Eagle 300 Ton

Platen Size: 130″ x 114″

Daylight: 97″ / Distance between tie bars: 130″ - Bondy 150 Ton

Platen Size: 86″ x 70″

Daylight: 89″ / Distance between tie bars 64″ - Fury 75 Ton

Platen Size: 60″ x 36″

Daylight: 70″ / Distance between tie bars 48″

Over Head Cranes

- 25 Ton Demag With 16 Ton Flipping Hoist

- 20 Ton Demag

- 20 Ton Kone With 10 Ton Flipping Hoist

- 14 Ton Demag

- 14 Ton Canadian Crane With 7 Ton Flipping Hoist